Description

The new standard for precision and speed

With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of 50 kHz, they offer the precision and speed necessary for the control of the strip thickness.

VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers.

WAs with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Simple and safe

An automatic air cleaning system for the measuring window and beam path and the innovative temperature compensation ensure the highest precision even under difficult environmental conditions. As the lasers conform to laser protection class 3B, no additional beam protection guards are necessary.

The principle – The technology in detail

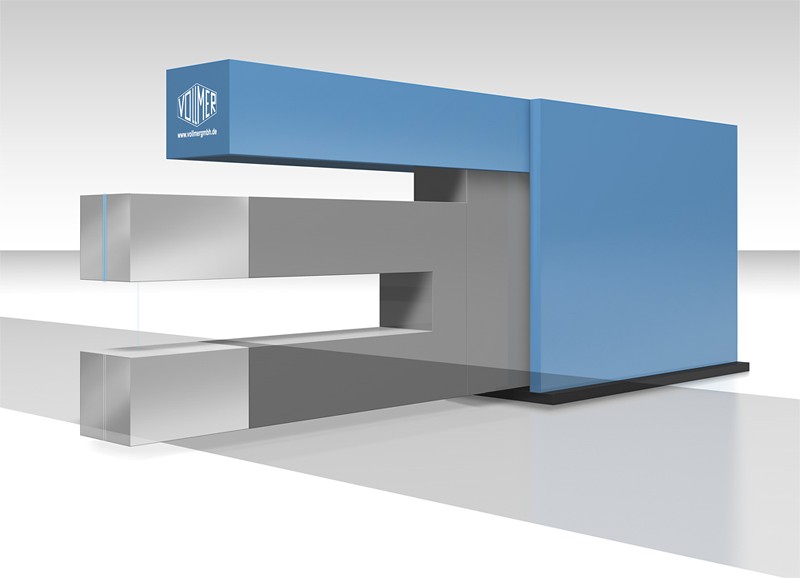

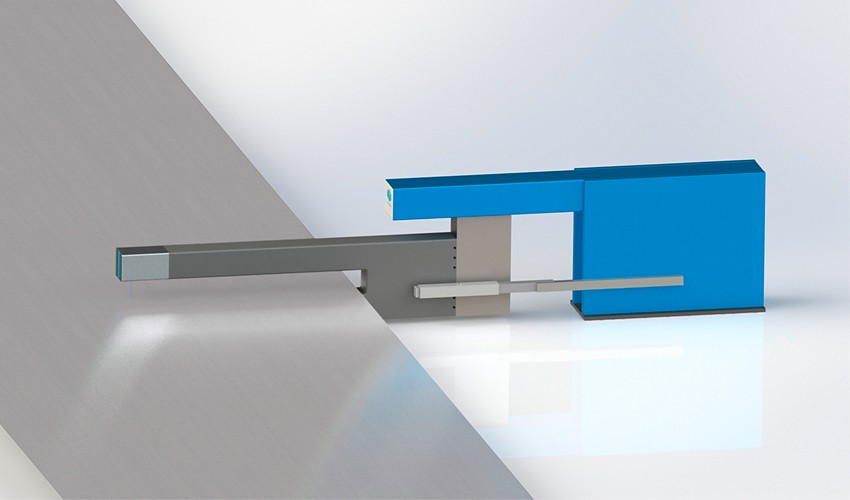

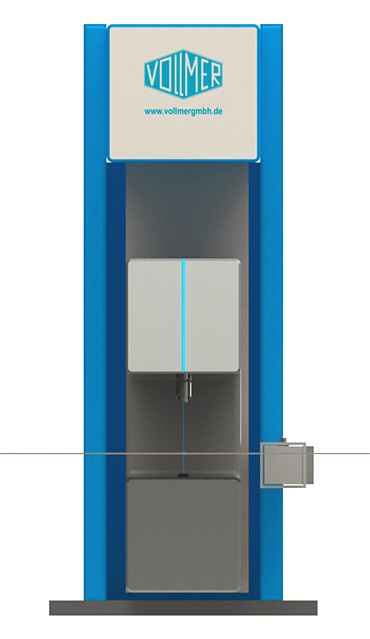

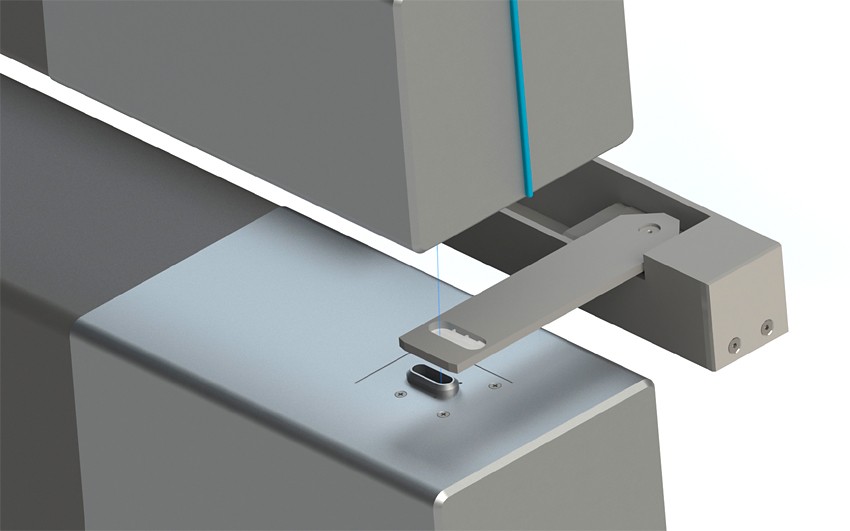

On the upper and lower sides of a C-frame is a compact measuring head which both transmits the measurement beam and receives the reflected light. Both sensors measure the distance from the strip surface from their perspective. The system then calculates the thickness of the strip from the measured distances and the distance between the two sensors.

The fact that the two sensors operate absolutely synchronously contributes significantly to the high precision of the systems. They are integrated into a sturdy, compact C-frame that moves out of the line automatically at the end of the strip.

With an internal scanning rate of 50 kHz, the scalable analog output provides the input signal for the high-speed thickness control within milliseconds.

Permanently accurate

Every time the C-frame moves into or out of its parking position alongside the strip, the measuring system passes through the permanently installed adjustment station. The system thereby measures the inserted captive gauge blocks representing the whole measuring range of the respective application. The VTLG calibrates itself and makes any necessary corrections automatically. This ensures that the system measures accurately at all times.

Data Sheet

[embeddoc url=”https://www.hsotomasyon.com/wp-content/uploads/2019/05/datenblatt-vtlg_en.pdf” download=”all” text=”İndir”]